FL2-25 Semi automatic hydraulic interlocking brick making machine

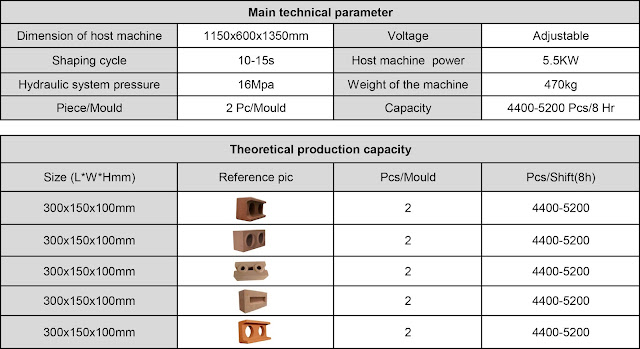

FL2-25 semi-automatic interlocking brick making machine is a small hydraulic block machine which can be easily operated by one person.And it has been widely used in African countries. Following are the detailed data of this machine 1. Function This machine can produce many different interlocking bricks by changing mould, such as hollow block with two holes or three holes, U shape block, solid block etc. 2. High production efficiency FL2-25 is a semi automatic block making machine and shaping cycle is 10-15s.The production efficiency is high with labor saving, it can produce 4400-5200 pieces per day. 3. Advanced technology Hydraulic pressure molding technology is adopted to this machine, and the pressure can arrive at 16MPa, so the brick machine has more stable and higher-efficiency working status and the bricks produced are of better quality, large density and higher strength. And we have two types of diesel power and electric power for your choice. 4. High quality mould O